Implementing High Speed Motor Bus Transfer Schemes for Critical Heavy Industry Applications

/City commuters often think about transferring between passenger bus routes to reach their final destination. In this blog, we discuss the merits of transferring electrical power sources between the distribution buses that feed electrical loads. Various configurations to accomplish this task have been available for many decades, yet some of these methods are not well understood. Some may think that automatic transfer upon loss of power (with a manual return) is the only option because that is the only design they’ve ever seen, but this is not the case. Let’s examine the options that are now available due to the advent of Intelligent Electronic Devices (IEDs).

Present-Day IEDs and Power Circuit Breakers

In the early decades of power circuit breaker development, stored (mechanical) energy might have been available only for tripping (opening) a circuit breaker because of the necessity to interrupt undesirable current on a given circuit, while most circuit breakers were often closed manually. Breakers that could be closed electrically were actuated by a rather massive solenoid that required substantial external current. Consequently, the breaker’s reaction time to a closing command was rather slow. In addition, electromechanical relays that were previously used to close and trip breakers were also rather slow to respond. As technology improved, the transfer between power sources began to be offered by switchgear manufacturers. Today, digital logic within IEDs and fast-acting 3-cycle power circuit breakers make bus transfer options more flexible.

The Classic “Main-Tie-Main” Configuration

The advantage of having two power sources (i.e. two main breakers) and a tie circuit breaker between them is to allow downstream operation when one source has been lost or has been de-energized for maintenance or other reasons. Usually, the sources are rated to carry the electrical load of both buses. When one source is removed, the normally open tie breaker is closed, which places both buses on the remaining active source. This can be done under the command of an operator, via a Supervisory Control and Data Acquisition (SCADA) system, or “automatically” by using voltage sensing, status feedback, and digital logic within IEDs at the switchgear. In any case the design and the equipment used makes for a “slow” transfer (i.e. greater than 20 cycles up to many seconds of time delay).

Restoration to ‘Normal’

The most common procedure for transfer back to the ‘normal’ configuration (restoration), after power is supplied by an alternate source, is done manually by an operator. The main reason for this philosophy is to avoid an unanticipated second interruption of power while the transfer is made. When power is interrupted during the restoration process, this is called an “open transition”, but that is not the only option. Modern IEDs can interact, with each one monitoring and protecting its respective source. When the previously unavailable source becomes available once again, the IEDs (relays) can be configured to determine if conditions are permissible and perform a “closed transition”. The closed transition is often called a ‘make before break’ sequence, where both sources are momentarily placed in parallel before the tie-breaker is opened, thereby restoring each bus to its respective incoming source. There are two methods commonly employed to ensure that paralleling is momentary. One is often called “kiss transition” where the status contacts on each breaker are arranged such that when both main breakers are closed, their contacts immediately trip the tiebreaker. Other schemes use an anti-parallel timer that detects all three breakers closed and trips the tie-breaker (or other selected breaker) after a short delay, thus allowing for a closed transition between any combination of sources.

In-Phase Transfer

One of the permissible conditions that a protective relay (or IED) can detect is that each respective source is “in-phase” within reasonable limits is through the function of the ANSI-25 synchronism-check device. This function can be augmented by any combination of the presence or absence of source and/or bus voltages or even the acceptable range of voltage difference. ANSI-27 elements in the IED supervise this. Many applications are such that the phase difference is nearly zero once the system has been properly installed. However, there are other applications where sources originate from different upstream substations with different switching conditions, or even different generating stations. Therefore, synchronism-checking is mandatory even for a “kiss” transition in order to prevent equipment damage.

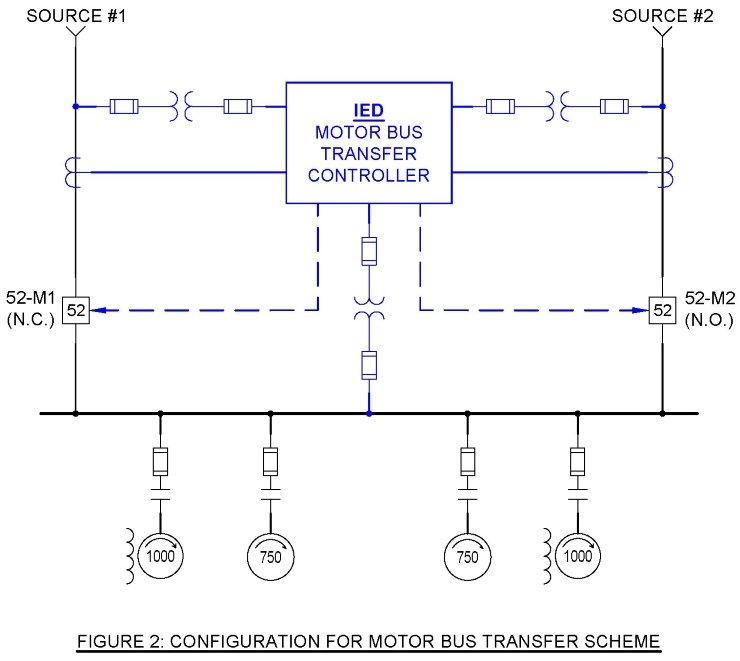

Motor Bus Transfer

Transferring bus loads between sources for the average industrial or commercial application can be done with the methods mentioned above. True, an outage is inconvenient – everything must be restarted, etc. On the other hand, there are some applications where an interruption of power is more than just an inconvenience: it prevents a successful start-up of a process. Industries such as power generation, petrochemical, cement, and paper have key buses where motors essential to the process are located. There is a significant amount of connected horsepower, and these motors are always running. In fact, the loss of these motors will interrupt the process that may have taken many hours, if not days to reach the point where a transfer of power can be made. This is the case where large boilers are brought into operation from a cold start, or a liquified natural gas (LNG) process is brought up from a warm start condition. The situation is unique to each process industry.

So far, the criteria necessary for transfers have been easily achieved by most IEDs. Motorbus transfers must consider system responses that require IEDs specifically designed for the purpose. This is because two very dynamic measurements must be made for a successful transfer. A transfer without losing the running motor load sounds like the best of all worlds, but it is not for everybody. The average industrial and commercial application may not benefit from this philosophy. This is because groups of small HP induction motors and passive front-end variable frequency drives (VFDs) expend all of their electromechanical energy in less than three cycles, motor starters drop out, and VFDs fault on Undervoltage within a very short time. For specialized industries, motor bus transfer relies on the factors listed below.

Fast-bus transfer (or motor bus transfer) pertains to any transfer scheme designed to prevent paralleling of the two sources but minimizes the time between when the first source is removed, and the alternate source is applied. Properly selected and timed devices can bring this time to less than 10 cycles (approximately 167 ms). Furthermore, the hold-in time for any starters associated with the motors is modified (if required) to be significantly longer than the transition time. But just arbitrarily closing the second source breaker can present problems because the motor bus, which has significant horsepower and rotational inertia that can remain energized with a residual voltage that decays in both magnitude and frequency as the motors begin to coast down. This is especially important when any synchronous motors are present on the bus. The supervising IED must be designed for both ANSI-27 and ANSI-25 sensing that is fast responding and accurate over a wide frequency range.

In-phase bus transfer is like previously described for parallel transfer, except that the comparison is made between the bus and the incoming source. Furthermore, the bus voltage, frequency, and phase angle are dynamically changing. When the angle of the residual bus voltage and the incoming source is near zero, the supervising IED triggers a transfer.

Residual-voltage bus transfer can be a fallback approach for a motor bus if the fast-bus and in-phase transfer opportunities were somehow missed. This option is designed to monitor the magnitude of the motor bus voltage after the first source has been removed (i.e. breaker opened) and not close the alternate source until the bus voltage has decayed to a ‘safe’ value (usually 0.2 per unit or less). This process usually takes longer than 10 cycles to complete. Residual voltage is permissive has long been used for the cement industry, where large horsepower synchronous motors with large inertial loads have been traditionally employed.