Startup & Commissioning

We provide startup and commissioning services to inspect, validate, and verify (IV&V) the construction integrity of both new and existing facilities undergoing modification. Our comprehensive services assure you that your systems have been delivered and installed in a safe, reliable, and fully functional manner.

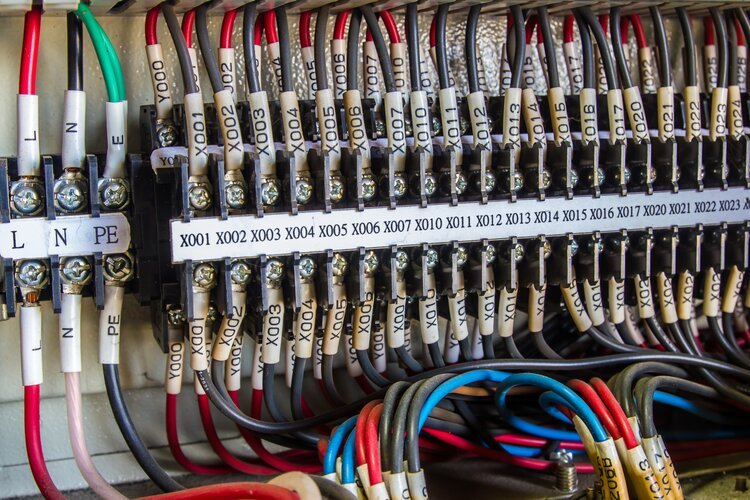

Verifying the proper functionality of hardware, software, and instrumentation systems ensure that your installed equipment suits your original application intent. Tasks including power system validation, electrical component checkout, wiring system verification, process control loop testing, PLC and HMI operation, register mapping, safety interlocking, and performance testing establishes the basis for meeting your operational requirements and for successful long-term functionality.

Our core competencies in startup and commissioning services:

Open & Closed Loop Testing

Open and closed loop testing, based on both online and offline evaluation, is used to verify the functionality of instrument devices, input setpoints, and tuning parameters to achieve stable, reliable control over an automation sequence or a process control system. Such testing helps ensure that any complex industrial I/O logic schemes will properly function as intended.

System Protection & Relaying

Verifying the proper operation of an electrical protection system ensures effective protection against faults for AC and DC equipment while safeguarding against nuisance tripping. Proper evaluation of advanced protection schemes such as directional overcurrent, reverse power, rate of rise protection, differential protection, transfer trip schemes, impedance relaying, and negative sequence protection is vital.

Power System Functionality

Power system functionality verification can assess and confirm the proper operation of the electrical distribution system in response to varying upstream conditions and the operational profile of downstream electrical and non-electrical loads. Proper operation includes automatic source transfer schemes, paralleling source synchronization, rectifier load balancing, load prioritization, and distributed cogeneration.

Safety Interlocking

Safety interlocking using electrical, electronic, or keyed mechanical devices helps prevent improper electrical operation and avoid undesired power system conditions. This includes preventing paralleling between unsynchronized sources, preventing access to energized compartments, blocking the closure of switching devices onto faulted buses, and ensuring features that thwart the defeat of lockout/tagout mechanisms.

Control Sequencing

Verifying the control sequencing of electrically operated systems ensure that electrical equipment and process loads operate by their desired functionality. This includes validation of phase rotation, proof testing of control schematics, ladder logic, interposing relays, motors, actuators, sensors, circuit breaker mechanisms, starter mechanisms, drive mechanisms, and connectivity with SCADA.

Instrument Calibration

The proper operation of instrument devices will ensure the accuracy of an overall instrumentation & control system and eliminate aspects that can otherwise cause inaccurate or erroneous system measurements. Such instruments can include mechanical switches, breaker cell switches, RTD thermocouple elements, analog sensors, current transformers, potential transformers, Bucholz relays, and level/flow devices.

In addition to performing IV&V services, our team can also be a long-term resource for you with equipment training, operation & maintenance, and documentation for standard operating procedures. We also develop methods of procedure for equipment inspection and maintenance as a roadmap for your long-term reliability. For specialty project applications involving complex electrical systems, the startup and commissioning services might include:

Safety Interlocking. Verification of electrical and mechanical interlocks for substations and power distribution equipment to prevent dangerous electrical operating conditions, ensure proper equipment protection, and establish safety for electrical personnel.

Control System Verification. Confirmation of electrical protection schemes to accomplish desired functionalities including high-speed relaying, redundant relaying, differential protection, pilot transfer trip (PTT), direct transfer trip (DTT), line impedance monitoring, negative sequence, synchronism check, and IEC 61850-based transfer tripping.

Generator System Validation. Verification of generator operation and interconnection systems including prime mover controls, turbine controls, anti-islanding protection, out-of-step protection, and loss of excitation to help maintain transient stability for a given electrical system.

Electrical Equipment Functionality. Proper functionality of motor control center centers, variable frequency drives, and control panels associated with water and wastewater facilities to ensure proper water treatment, wastewater treatment, and water distribution, and to avoid public health and ecological consequences.

Power System Functionality. Proper functionality of switchgear lineups, rectifier transformers, rectifiers, rectifier load balancing, frequency converters, AC/DC relaying, short circuit testing, and control systems associated with AC and DC traction power systems for railway electrification.

Communication System Operation. Verification of communication architecture, system alarming, real-time connectivity, and data exchange between electrical equipment and with remote control devices using hardwired signaling and communication protocols including Modbus, DNP3, Mirrored Bits, and IEC 61850 GOOSE messaging.