Electrical Inspection

We perform inspection services to investigate and identify problem areas within electrical distribution systems. Our thorough services help you mitigate risks, assist with the latest code compliance, and call attention to impending equipment failure or possible system downtime. Our approach ensures that your electrical system will continue to function to meet your facility’s operational needs and fulfill your mission by concentrating on maintenance efforts where they count most.

A comprehensive electrical inspection helps you to know that your electrical system is safe to operate and by all applicable building codes, local electrical codes, safety standards, and equipment manufacturer guidelines. Beyond code compliance, our inspection team provides you with the added benefit by performing an expanded condition assessment of your electrical equipment. Using our proprietary condition assessment methodology, we can analyze your equipment’s test data to compare it against similar known electrical equipment, ascertain its useful life, and provide you with recommendations to render the equipment suitable for continued operation. Our engineers and electricians combine their experience to perform visual inspections, electrical testing when necessary, and then draw an estimate on the remaining useful life for existing equipment.

Our core competencies in electrical inspection services:

Condition Assessment

A comprehensive equipment condition assessment compares the overall integrity of electrical equipment against industry specifications, applied fault duty, physical condition and functionality of pilot devices, functionality of auxiliary control devices, evaluation of equipment degradation, and the examination for the presence of hazardous materials.

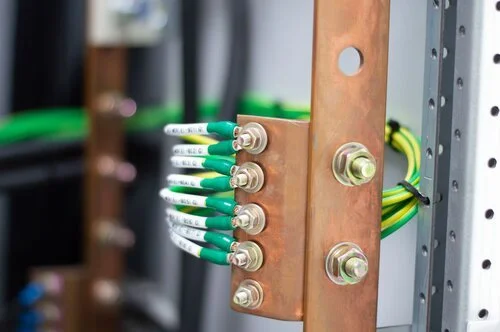

System Grounding

System grounding verification focuses on personnel protection against touch potential, step potential, and stray voltages. This also includes verifying proper ground current return paths and for the proper application of grounding electrode systems, equipment grounding, bonding, and earthing systems, impedance grounding, ungrounded systems, and lightning protection systems.

Code Compliance

A plan layout and code compliance review ensures that electrical facilities comply with NEC requirements, including means of egress, working space, dedicated space, clear space, adequate illumination, arc flash labelling, grounding, bonding, wiring methods, overcurrent protection, selective coordination, and life safety system requirements.

Power Quality Analysis

Power quality analysis is undertaken to verify that voltage and current waveforms are as expected for the configuration, reasonably free of distortion, and balanced overall. Detailed analyses can include the assessment of voltage sags, swells, momentary disruptions, flicker, ground noise, transients, harmonics, power factor, voltage imbalance, and current imbalance.

Third Party Inspection

Third-party inspection ensures that electrical installations and electrical systems are in accordance with industry-recognized standards, building codes, NEC, customer specifications, and are deemed suitable for reliable operation. An autonomous third-party inspection can validate the proper installation of electrical facilities with an impartial and unbiased perspective.

Infrared Thermography

Infrared thermography can identify emerging problems within electrical equipment that are attributed to excessive heat rise. When scrutinized, infrared inspections can also help pinpoint impending trouble, such as loose wiring connections, imbalanced and/or overloaded circuits, defective breakers, damaged switches, faulty fuses, and insulation breakdown.

In addition to the early identification of potential problem areas within an electrical system, an electrical inspection will minimize the risks associated with lost production and downtime attributed to electrical equipment damage. Improper electrical system configuration often increases utility bills, may cause long-term damage to critical loads, result in higher operating costs, and increase the likelihood of a prolonged system outage. For specialty project applications involving complex electrical systems, comprehensive electrical inspection services might include any of the following:

Electrical Equipment Assessment. Visual and mechanical inspection of electrical equipment to determine overall integrity of the equipment compared to NEMA/ANSI specifications. Observation and assessment consider the general condition and functionality of pilot devices, functionality of auxiliary control devices and relays, evaluation of electrical degradation, and determination of the presence of hazardous materials within components.

Electrical System Grounding. Verification of grounding systems in accordance with the requirements of IEEE 80/81 and NEC to ensure protection against touch potential, step potential, and stray voltages. This includes the proper application of grounding electrode systems, equipment grounding, bonding, earthing systems, impedance grounding, and the proper treatment of ungrounded systems.

Short Circuit Duty. Verification of short circuit withstand ratings (kA) for electrical equipment and the ampere interrupting capacity (AIC) for protective devices. This ensures that electrical equipment is properly rated and well below maximum of the possible fault currents supplied from upstream equipment and its protective devices are properly rated to trip during a short circuit condition. This can be done by comparison to an existing power system study or by reasonable estimates using observed data.

Code Compliance. Inspection of electrical facilities to ensure compliance with the requirements of building codes and the NEC with regard to aspects including means of egress, working space, dedicated space, clear space, adequate illumination, arc flash labelling, grounding, bonding, wiring methods, overcurrent protection, selective coordination, and life safety systems.

IR Scanning and Inspection. Infrared thermography to identify emerging problems within electrical equipment that are attributed to excess heat rise either due to improper installation or defective components. Infrared inspections are non-contact and non-destructive, and they often help pinpoint impending trouble such as loose connections, imbalanced and/or overloaded circuits, defective breakers, damaged switches, faulty fuses, and insulation breakdown.

Power Quality Analysis. Inspection and analysis of measured voltage and current waveforms for a given configuration, reasonably free of distortion, and balanced overall thereby avoiding conditions that can otherwise compromise electrical system performance. Detailed analyses include assessment of voltage sags, swells, momentary disruptions, flicker, ground noise, phase and ground transients, current and voltage harmonics, power factor, and system imbalance (negative sequence).