How Accurate Cable Modeling Will Ensure the Accuracy of Your Arc Flash Incident Energy Analysis

/Failure to protect personnel adequately against injury or death from an arc flash event can financially decimate a company. The failure to comply with the requirements and guidelines of the Occupational Safety and Health Administration (OSHA), National Electrical Code (NEC), and National Fire Protection Association (NFPA) 70E can cost you time and money through fines and unexpected downtime. In this article, we will be exploring one piece of data in Arc Flash Study models: cables, specifically the effect of length on the accuracy of incident energy calculations.

Arc Flash Risk Assessment

Performing an arc flash risk assessment can identify their potential threats and estimate the extent of the arc flash incident energy exposure. Every major piece of electrical equipment could potentially cause harm to anyone performing electrical maintenance tasks, and the goal is to identify how much harm and how to prevent it. NFPA 70E, Article 130.5(A) states that an arc flash risk assessment shall be performed to identify arc flash hazards and estimate the likelihood of an injury occurring. In other words, each significant point in the electrical system should be analyzed to determine the possible danger for electrical personnel.

Incident Energy Analysis Method

The arc flash incident energy calculations consider the magnitude of the arcing fault and the time it takes for the protective device to trip or clear that fault. NFPA 70E, Article 130.5(G) describes the calculation methodology to determine arc flash incident energy at a given working distance. There are a few especially relevant items that relate to this article. The accuracy of the cable information input into the study model will significantly affect the calculated arc fault current.

Significance of Cable Size and Length

Cables are one of the many complex impedance elements in an electrical distribution system. With an elementary understanding, let’s look at the significance of cable sizes and lengths in a given scenario. In fundamental terms, the fault current in a system is determined by using Ohm’s Law. The fault current is calculated by dividing the nominal system voltage by the equivalent system impedance [I = V/R]. Each electrical cable has a complex impedance. In generalized terms, as the cable impedance increases, the fault current at a given location will decrease.

In conjunction with this, the arc flash incident energy considers the time it takes the protective device to trip and clear the arc fault. As seen in the Time Current Curve (TCC) below, each fault current will take a different amount of time to trip the protective device. For higher fault current values, the device will trip faster. For lower fault current values, this condition is allowed to persist a little longer to allow momentary overloads and establish protective device coordination. The varying tripping time can lead to the unexpected possibility of higher incident energy at either a lower fault current value or a higher fault current value.

Accuracy of Cable Lengths for the Arc Flash Risk Assessment

Whether collecting data or performing an arc flash study, it is vital to have accurate impedance information in the model. But the question is, how accurate do the cable lengths need to be for an arc flash study? With all this background information considered, an example system will be analyzed to see the effect of changing cable lengths.

In the example below, let us consider an electrical system where Switchgear-X supplies power to Switchgear-Y. By varying the cable length between Switchgear-X and Switchgear-Y with all other factors being kept relatively constant, the calculated arc flash incident energy will be changed at Switchgear-Y. The variation is further impacted by the variation in the nominal voltage of the electrical system.

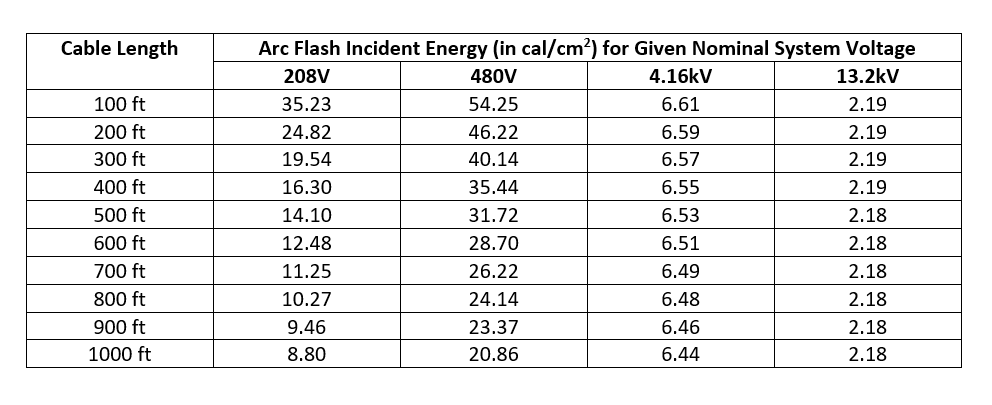

The table below summarizes the calculated Arc Flash Incident Energy at Switchgear-Y, based on a given nominal system voltage and cable length, assuming that all other parameters are maintained relatively constant.

As observed from the table, the cable length significantly impacts the incident energy, especially at lower nominal system voltages (208V and 480V). When performing data collection, determining accurate cable length is vital to calculate arc flash incident energy levels accurately for lower voltage systems. Complete cable information is the best way to ensure personnel protection for electrical personnel.

Accurate power system studies must be performed to keep electrical personnel safe. Contact us for recommendations to suit your specific electrical safety requirements or if you need help interpreting OSHA, NEC, NFPA 70E, and IEEE 1584. For a free consultation on arc flash mitigation options available to you, call us at (240) 582-3900 or email us at info@helioselectric.net.

To learn about our other unique solutions that can enhance your electrical facilities, click here.